Technology Development Status

The continuous technology development is the mission of Techvalley

-

2020 In-Line Automated X-ray CT Inspection System

We developed an automated in-line CT that can be used in production lines at high inspection accuracy, repeatability, and fast inspection speed by easy use and AI software considering user convenience.

We developed an automated in-line CT that can be used in production lines at high inspection accuracy, repeatability, and fast inspection speed by easy use and AI software considering user convenience. -

2019 Automated X-ray Chip Counter Upgrade

In 2013, the world's first developed chip counter was upgraded. (It can inspect 4 reels at the same time and inspect various packaging materials such as chips of various sizes and JEDEC trays and tubes)

In 2013, the world's first developed chip counter was upgraded. (It can inspect 4 reels at the same time and inspect various packaging materials such as chips of various sizes and JEDEC trays and tubes) -

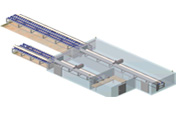

2018 In-Line Automated X-ray Inspection System with Dual Tubes

We have developed a In-Line Automated X-ray Inspection System with Dual Tubes. Due to the installation of the dual tubes, the defect of the sample you want can be inspected at multi-dimensional, and it can be inspected twice with one sample input, so it can be inspected quickly.

We have developed a In-Line Automated X-ray Inspection System with Dual Tubes. Due to the installation of the dual tubes, the defect of the sample you want can be inspected at multi-dimensional, and it can be inspected twice with one sample input, so it can be inspected quickly. -

2017Optimization of In-Line Automated X-ray Inspection System

After developing automated In-Line X-ray equipment that allows overlapping inspection in 2016, we developed equipment that diversifies performance and size and realized optimization so that it can be inspected according to various samples of users.

After developing automated In-Line X-ray equipment that allows overlapping inspection in 2016, we developed equipment that diversifies performance and size and realized optimization so that it can be inspected according to various samples of users. -

2016 In-Line AXI(Automated X-ray Inspection) 2.5D System

AXI / 2.5D system is the innovative equipment that adopts the technologies that can take the inspection sample in various directions rather than one direction, analyze the image by software, and view, analyze the superimposed image in 2.5D dimensions.

AXI / 2.5D system is the innovative equipment that adopts the technologies that can take the inspection sample in various directions rather than one direction, analyze the image by software, and view, analyze the superimposed image in 2.5D dimensions. -

2015 Portable X-ray fluorescense (XRF) – The 1st in Korea

Techvalley developed the portable X-ray fluorescense(XRD) device system that was dependent on import only for the first time in Korea, and succeeded in optimizing the system through RoHS standard sample of KRISS(Korea Research Institute of Standards and Science).

Techvalley developed the portable X-ray fluorescense(XRD) device system that was dependent on import only for the first time in Korea, and succeeded in optimizing the system through RoHS standard sample of KRISS(Korea Research Institute of Standards and Science). -

2014 In-Line AXI(Automated X-ray Inspection) System

In-Line AXI(Automated X-ray Inspection) system, which adopts the innovative inspection system that analyzed the inspection image through special filter processing, has entered into the global market and installed directly in the SMT line in Vietnam, China, Malaysia, Mexico, etc.

In-Line AXI(Automated X-ray Inspection) system, which adopts the innovative inspection system that analyzed the inspection image through special filter processing, has entered into the global market and installed directly in the SMT line in Vietnam, China, Malaysia, Mexico, etc. -

2013 X-ray automated reel chip counter – The 1st in the World

The automated X-ray chip counter developed for the first time in the World completely solves the disadvantages and limitations of the existing electric reel chip counter and provides a perfect automated inspection environment by simply moving the conveyor. Especially, from 180mm compact general reels to large reels up to 380mm size can be counted within 13~22 seconds.

The automated X-ray chip counter developed for the first time in the World completely solves the disadvantages and limitations of the existing electric reel chip counter and provides a perfect automated inspection environment by simply moving the conveyor. Especially, from 180mm compact general reels to large reels up to 380mm size can be counted within 13~22 seconds. -

2012 Small-Angle X-ray Scattering (SAXS) – The 1st in Korea

SAXS system can get lots of information from sample materials, such as size, distribution, Morphology and orientation distribution of particles. Especially strongly useful for nano-structured materials in non-destructive structure evaluation.

SAXS system can get lots of information from sample materials, such as size, distribution, Morphology and orientation distribution of particles. Especially strongly useful for nano-structured materials in non-destructive structure evaluation. -

2011 X-ray diffractometry system (XRD) – The 1st in Korea

XRD system can possible from the measuring of powder to structural analysis single crystal. Techvalley XRD system replaced all imported equipment with own developed new system.

XRD system can possible from the measuring of powder to structural analysis single crystal. Techvalley XRD system replaced all imported equipment with own developed new system. -

2011 X-ray CT system for internal measurement – The 1st in Korea

3D measurement technology system based on CT technology for the first time in Korea. The No.1 X-ray system having the best quality analysis ability and reliability.

3D measurement technology system based on CT technology for the first time in Korea. The No.1 X-ray system having the best quality analysis ability and reliability. -

2010 Digital X-ray CT system for geological inspection – The 1st in Korea

Applied for exploration of hydrate and petroleum in East-sea. It were set up KIGAM (Korea Institute of geoscience and mineral resources) at Daejeon, Korea in 2010.

Applied for exploration of hydrate and petroleum in East-sea. It were set up KIGAM (Korea Institute of geoscience and mineral resources) at Daejeon, Korea in 2010. -

2007 Automated X-ray inspection system for steel pipe – The 1st in Korea

Techvalley developed the equipment that can automatically inspect and read 12m steel pipe within one minute and mark defective part for the first time in Korea. In addition developed a quality management system by building a perfect database.

Techvalley developed the equipment that can automatically inspect and read 12m steel pipe within one minute and mark defective part for the first time in Korea. In addition developed a quality management system by building a perfect database. -

2006 Industrial X-ray CT system – The 1st in Korea

Corn-bean type X-ray CT was developed by Techvalley for the first time in Korea.

Corn-bean type X-ray CT was developed by Techvalley for the first time in Korea.

Techvalley installed at Seoul National University of Science & Technology, Samsung Techwin and LG chem, etc. -

2005 Developed X-ray generator (160kV class) – The 1st in Korea

Techvalley developed X-ray integral type generator that 110kV & 160kV class a year after introduced 80kV generator. New X-ray generator were used for die-casting, assemblies of automotive parts, etc.

Techvalley developed X-ray integral type generator that 110kV & 160kV class a year after introduced 80kV generator. New X-ray generator were used for die-casting, assemblies of automotive parts, etc. -

2004 Developed X-ray generator (80kV class) – The 1st in Korea

Techvalley developed the 80kV class X-ray generator for the first in Korea and star ted to install the equipment in earnest. The year of 2004 was recorded in the first year of localization X-ray related parts in Korea.

Techvalley developed the 80kV class X-ray generator for the first in Korea and star ted to install the equipment in earnest. The year of 2004 was recorded in the first year of localization X-ray related parts in Korea. -

2003 Automated X-ray inspection system for PCB hole alignment – The 1st in the World

Techvalley have jointly developed with Samsung Electro-Mechanics and applied for a joint patent.

Techvalley have jointly developed with Samsung Electro-Mechanics and applied for a joint patent. -

2002 Digital X-ray inspection system for eccentricity of PCB hole – The 1st Korea

PCB hole eccentric inspection equipment which depend on import was localized at the request of Geoyang Co., Ltd, and became No.1 in market share in Korea.

PCB hole eccentric inspection equipment which depend on import was localized at the request of Geoyang Co., Ltd, and became No.1 in market share in Korea. -

2001 Digital X-ray inspection system for relics – The 1st in Korea

In case of inspection for relics or cultural properties, used only Japanese equipment.

In case of inspection for relics or cultural properties, used only Japanese equipment.

Techvalley developed this system for the 1st time in Korea at the request of the National Museum of Korea. -

2000 Micro-focus X-ray inspection system for electronic parts – The 1st in Korea

As the electronic parts become light & thin, ask to be inspected by high magnification (100 to 200 times). Techvalley answered for development demand of customer.

As the electronic parts become light & thin, ask to be inspected by high magnification (100 to 200 times). Techvalley answered for development demand of customer. -

1997 Portable digital X-ray fluoroscopy equipment – The 1st in the World

Portable digital X-ray fluoroscopy equipment using battery as power source. Techvalley was awarded a silver medal at the Korea Patent Tech. competition and a Grand Prize at the IIE(International Invention Exhibition), etc.

Portable digital X-ray fluoroscopy equipment using battery as power source. Techvalley was awarded a silver medal at the Korea Patent Tech. competition and a Grand Prize at the IIE(International Invention Exhibition), etc.

History

Techvalley’s history is the history of Korean industrial X-ray inspection system.

Accomplishment

We are always move to idea centric for our clients