AXI (Automated X-ray Inspection) System

AXI(Automated X-ray Inspection) system is a revolutionary automated X-ray inspection system that has built-in image analysis software and automatically determines the goodness and badness of the inspection sample using the image acquired by the inspection equipment itself. It is optimized for industry and precision parts inspection of mass production system structure requiring full inspection. Especially, it is X-ray inspection equipment which can perform automatic inspection of in-line. AXI system can be inspected include SMT line mounting parts, mobile phone battery, mobile phone camera actuator ball, LED, speaker and microphone for mobile phone, condenser, USIM tray, semiconductor and automobile ECU board.

3D CT (Computerized Tomography) System

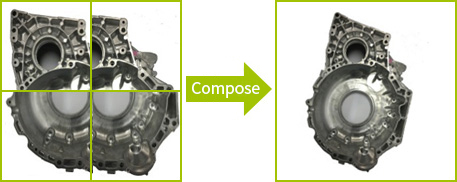

The 3D CT is a method of acquiring a three-dimensional image by mathematically combining two-dimensional projection images of an X-ray continuously shot by rotating the sample to be measured 360 degrees and analyzing the image. Performing a precise analysis of the analytical object, such as three-dimensional comparison analysis, quantitative failure analysis of internal defects, quantitative analysis of thickness indices in 3-D and 3-D design verification, Can be professional inspection equipment. In addition to statistical analysis through standard vs. actual data analysis, it is possible to extract CAD data using surface information by extracting design data. This means that not only internal defect analysis but also various analysis can be done through 3D design verification. In addition, Techvalley's 3D CT equipment provides a virtual scan function that moves samples larger than the size of the detector, moving them vertically and horizontally, and composing them into one 3D image.

TVX-IL series provides the world's best CT analysis function with Smart 3D CT inspection equipment made by the best CT development specialist group in Korea. Basically, the structure of the installed software and equipment is the same, but the model is divided according to the output of the X-ray source. Various sizes of samples can be inspected and internal void automatic grade analysis tool can be provided to standardize the inspection of bubbles by anyone. Techvalley provides customers with the world's best CT analysis functions, and is the first in the industry to offer the Korean manual (VG Studio) of analysis software.

TVX-IMT series is a specialized Micro 3D CT device designed and manufactured through Techvalley technologies and abundant field experience. It is widely used not only for industrial use but also for research and development. Due to the characteristics of Micro CT, it is optimized for small precision components and has exclusion function for image distortion and image superimposing. It is a high-tech equipment that can not be designed, manufactured and delivered unless its technology is supported because it uses high-magnification, high-precision X-ray image. Techvalley has a lot of experience in government offices, universities, research institutes, and other companies.

Dual CT System

Dual 3D CT equipment consists of dual X-ray source, most of which is designed and manufactured as an unmanned isolation type. It is designed, manufactured, and installed to meet the specific requirements of companies, research institutes, universities, . It is a state-of-the-art equipment that has been used for a wide range of purposes for the development and inspection of samples, cultural properties, and new materials ranging from small to medium-sized components, depending on the conditions of the installation site and inspection sample.

Techvalley has designed and make Dual 3D CT equipped with 800kV and 600kV Dual X-ray Source for the first time in the world. In addition, Techvalley, which operates the only video software team in Korea, has newly developed the history of domestic 3D CT inspection equipment by developing VG Studio operation, which is an analysis program dedicated to 3D CT, and core image related software.

Technique for synthesizing images in 3D by moving the detector vertically and horizontally without destroying (cutting) inspection specimens larger than the existing maximum detector size. (Unique inKorea)

2D X-ray series

The Techvalley 2D X-ray series is equipped with self-image analysis software capable of measuring and analyzing various samples. It is a professional inspection equipment with compact design and user-friendly design. It has the same or advanced detection capability compared to foreign equipment, but it is advantageous in terms of maintenance. As a result, customers can select various models according to the size, material and characteristics of the inspection target and apply them to the production site. Automatically categorize and save captured X-ray images, and achieve the highest inspection speed and accuracy. The world's highest quality X-ray source and high-resolution industrial detector are applied for more accurate and precise 2D X-ray image acquisition and analysis. It is made by shielding cabinet, which is designed as a double structure, also provides complete shielding of radiation and consideration of user and fields safety.

The TVX-IM series is a dedicated inspection device for inspecting precise electrical and electronic parts at reasonable cost. It is basically equipped with auto warming function. The TVX-IM2000 is an entry-level model for small parts inspection. It is an economical and affordable inspection tool for SMT and electronic parts. The TVX-IM9000 is an upgrade model of TVX-IM2000. It is optimized for inspection. In addition, TVX-IMT series is a high-precision 2D X-ray inspection system that can inspect not only small electronic parts but also small steel parts. It is a high-quality inspection system that eliminates edge distortion of X-ray image.

The TVX-IL series was developed for the first time in 2007 and has been proven in many industrial fields over the years. It is optimized for high-density casting inspection such as automobile parts, high-density casting, Al, Mg, etc., various kinds of plastic and rubber injection molding materials, and boasts outstanding defect detection ability with powerful image processing function. In addition, by adopting the CT module for die casting and auto parts inspection for the first time in Korea, the limitation of flat inspection is upgraded to the level of CT analysis software, and it is possible to analyze the structure of the mold in details.

Security, Research and Analysis Equipment (Discontinued Models)

Phoenix3000 (Phoenix2000), TVXA-ENIF1 (SAXS), ENIF2-Standalone (XRD), ENIF2-Benchtop (XRD), and TVXA-ENIF3 (XRF), developed by Techvalley for security and research, are now discontinued.

The Phoenix3000 (Phoenix2000) was developed by organizations that needed security such as airports, terminals, and military units.

Research analysis equipment XRD(X-ray diffractometer) and SAXS(X-ray small angle scattering device) were first developed in Korea in 2011 and 2012.

In 2015, Techvalley also developed the portable XRF(X-ray fluorescence device) for the first time in Korea and have succeeded in optimizing the system through the RoHS standard sample of the KRISS(Korea Research Institute of Standards and Science). Techvalley also has unique know-how in X-ray analysis equipment.